洗砂设备

洗砂设备

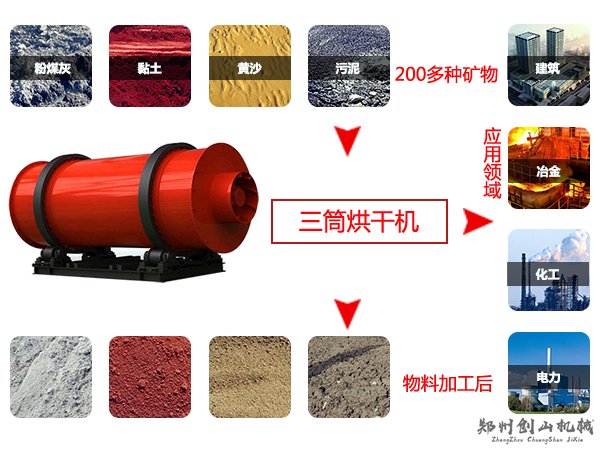

三筒烘干机

发布:admin 浏览:

应用领域

application area

产品优势

01耗能量低

三筒烘干机选用合理的运行参数,煤耗量和电耗量比一般烘干机减少10%-15%。

02热效率高

采用顺流干燥方式,物料与热源气流由同一侧进入干燥设备,烘干机出口温度低,热效率高。

03 处理量大,占地面积小

气流干燥器结构简单,占地面积小,易于建造和维修。处理量大,热效率高。

04结构简单,操作方便

结构优良﹑简单﹑物料通过筒体阻力运行平稳﹑操作方便。

Product advantages

01 low energy consumption

The coal consumption and power consumption of the three drum dryer are 10% - 15% less than that of the general dryer with reasonable operation parameters.

02 high thermal efficiency

By adopting the forward flow drying method, the material and heat source air flow enter the drying equipment from the same side. The outlet temperature of the dryer is low and the thermal efficiency is high.

03 large capacity, small floor area

The air dryer has the advantages of simple structure, small floor area and easy construction and maintenance. Large capacity and high thermal efficiency.

04 simple structure and convenient operation

It has the advantages of excellent structure, simple operation, smooth operation and convenient operation.

三筒烘干机生产线

Three cylinder dryer production line

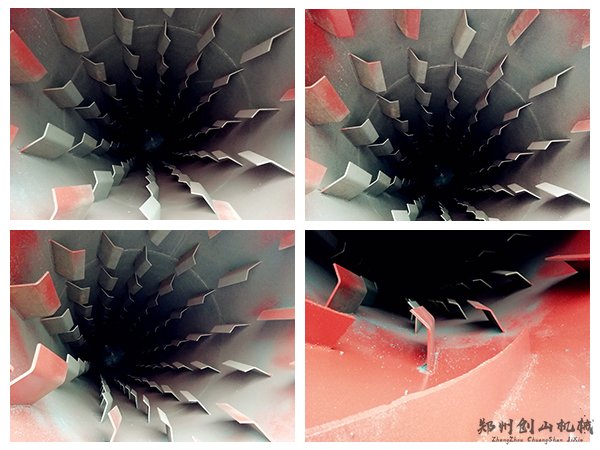

图片实拍

Picture shooting

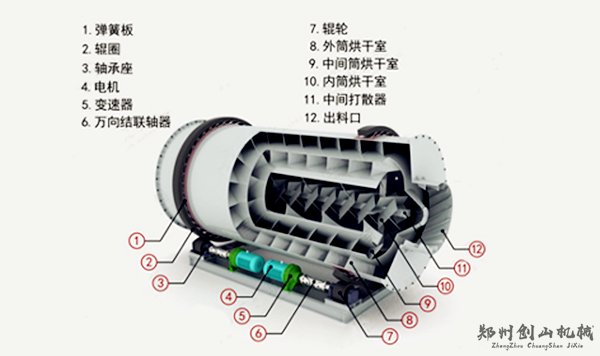

三筒烘干机结构图

Structural drawing of three cylinder dryer

工作原理

三回程烘干机的热源来自燃烧装置,本烘干机采用顺流式加热方式。因此需要烘干的物料,从进料箱、进料溜进入筒体,即被螺旋抄板推向后。由于烘干机倾斜放置,物料一方面在重力和回转作用下向后端流动,另一方面物料被抄板反复抄起,带至上端再不断地扬撒下来,使物料在筒内形成均匀的幕帘,与筒内的热气流进行热交换,由于物料反复扬撒,所含的水分逐渐被烘干,从而达到烘干的目的。

working principle

The heat source of the three return dryer comes from the combustion device, and the dryer adopts the forward flow heating mode. Therefore, the materials that need to be dried slip into the cylinder body from the feed box and feed, that is, pushed back by the screw plate. Due to the tilt of the dryer, on the one hand, the material flows to the back end under the action of gravity and rotation, on the other hand, the material is repeatedly picked up by the plate, carried to the upper end and then continuously spread down, so that the material forms a uniform curtain in the cylinder, and carries out heat exchange with the hot air flow in the cylinder. As a result, the moisture contained in the material is gradually dried to achieve the purpose of drying.

技术参数

technical parameter

规格(m)

(直径×长度)

|

筒体容积

(m³)

|

生产能力

(t/h)

|

安装斜度

(%)

|

最高进气温度

(℃)

|

主电动机

(kw)

|

总重量

(t)

|

Φ1.2×8.0

|

9.0

|

1.9-2.4

|

3-5

|

700-800

|

7.5

|

9

|

Φ1.2×10

|

11.3

|

2.4-3.0

|

3-5

|

700-800

|

7.5

|

11

|

Φ1.5×12

|

21.2

|

4.5-5.7

|

3-5

|

700-800

|

15

|

18.5

|

Φ1.5×14

|

24.7

|

5.3-6.6

|

3-5

|

700-800

|

15

|

19.7

|

Φ1.5×15

|

26.5

|

5.7-7.1

|

3-5

|

700-800

|

15

|

20.5

|

Φ1.8×12

|

30.5

|

6.5-8.1

|

3-5

|

700-800

|

18.5

|

21.5

|

Φ1.8×14

|

35.6

|

7.6-9.5

|

3-5

|

700-800

|

18.5

|

23

|

Φ2.2×12

|

45.6

|

9.7-12.2

|

3-5

|

700-800

|

22

|

33.5

|

Φ2.2×14

|

53.2

|

11.4-14.2

|

3-5

|

700-800

|

22

|

36

|

Φ2.2×16

|

60.8

|

13.0-16.2

|

3-5

|

700-800

|

22

|

38

|

Φ2.4×14

|

63.3

|

13.5-16.9

|

3-5

|

700-800

|

37

|

45

|

Φ2.4×18

|

81.4

|

17.4-21.7

|

3-5

|

700-800

|

37

|

49

|

Φ2.4×20

|

90.4

|

19.3-24.1

|

3-5

|

700-800

|

45

|

54

|

Φ2.4×22

|

99.5

|

21.2-26.5

|

3-5

|

700-800

|

45

|

58

|

Φ2.6×24

|

127.4

|

27.2-34.0

|

3-5

|

700-800

|

55

|

73

|

Φ3.0×20

|

141.3

|

30.1-37.7

|

3-5

|

700-800

|

75

|

85

|

Φ3.0×25

|

176.6

|

37.7-47.1

|

3-5

|

700-800

|

75

|

95

|

Φ3.2×25

|

201

|

42.9-53.6

|

3-5

|

700-800

|

90

|

110

|

Φ3.6×28

|

285

|

60.8-76.0

|

3-5

|

700-800

|

160

|

135

|

洗砂设备

洗砂设备