砂石设备

砂石设备

对辊式破碎机

发布:admin 浏览:

对辊式破碎机

Roller crusher

本系列破碎机是我公司研制的用于粗细碎的破碎设备。该辊式破碎机广泛应用于冶金、建材、耐火材料等工业部门破碎中、高等硬度的物料。它采用新的制造技术,特别的结构设计,加工成品呈立方体,无张力和裂缝,粒形相当好,其排料粒度大小可以调节,破碎规格多样化,同时具有噪音低、粉尘少、性能可靠、维修方便等特点。

This series of crushers are used for coarse and fine crushing developed by our company. The roller crusher is widely used in metallurgy, building materials, refractories and other industrial sectors to crush medium and high hardness materials. It adopts new manufacturing technology and special structural design. The finished product is cubic, no tension and crack. The particle shape is quite good. The size of discharging granularity can be adjusted. The crushing specifications are diversified. At the same time, it has the characteristics of low noise, less dust, reliable performance and convenient maintenance.

产品性能

噪音低,性能可靠: 采用转子重型化设计,改进板锤固定方式。该技术可使对辊破技术生产实力更硬,性能稳定可靠,降低噪声污染,在人文关怀的基础上,起到绿色环保的效果。

易损件寿命长,损耗小: 辊皮质量好、磨损周期长,易损件采用目前国内新高强耐磨材料,能破碎高硬度材料,损耗小,使用寿命长,比日常易损件可提高20%寿命,能为客户带来可观的经济效益。

生产效率高,处理量大: 该设备采用低悬挂运动机构设计,提供更大破碎比,经过破碎的物料呈立方体状,针片状含量低,无内裂缝,出料粒度细,提高了生产质量和效率。

适用范围广: 该产品在采用的石打石原理,节省能源的基础上,可扩大适用物料范围,适用于所有中高硬度的物料,可根据具体需求进行随意调配。

Product performance

Low noise and reliable performance: heavy duty rotor design is adopted to improve the fixing mode of plate hammer. This technology can make the production strength of roll breaking technology more rigid, the performance is stable and reliable, reduce the noise pollution, and play a green environmental protection effect on the basis of humanistic care.

The wearing parts have long service life and small loss: the roller skin has good quality and long wear cycle. The wear parts are made of new high-strength wear-resistant materials in China, which can crush high-hardness materials with small loss and long service life. Compared with daily wearing parts, the service life can be increased by 20%, which can bring considerable economic benefits to customers.

High production efficiency, large processing capacity: the equipment adopts low suspension movement mechanism design, which can provide greater crushing ratio. The broken materials are cube shaped, with low needle plate content, no internal cracks, and fine discharge particle size, which improves the production quality and efficiency.

Wide range of application: Based on the principle of stone striking stone and energy saving, the product can expand the scope of applicable materials and apply to all medium and high hardness materials. It can be randomly allocated according to specific requirements.

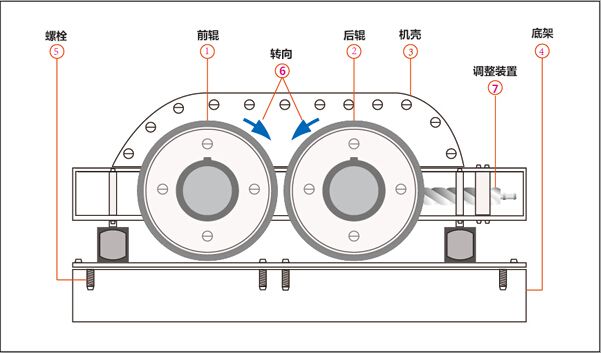

工作原理

出料粒度的调节:两辊轮之间装有楔形或垫片调节装置,楔形装置的顶端装有调整螺栓,当调整螺栓将楔块向上拉起时,楔块将活动辊轮顶离固定轮,即两辊轮间隙变大,出料粒度变大,当楔块向下时,活动辊轮在压紧弹簧的作用下两轮间隙变小,出料粒度变小。垫片装置是通过增减垫片的数量或厚薄来调节出料粒度大小的,当增加垫片时两辊轮间隙变大,当减少垫片时两辊轮间隙变小,出料粒度变小。

working principle

Adjustment of discharge particle size: wedge or gasket adjusting device is installed between two rollers, and adjusting bolt is installed at the top of wedge device. When the adjusting bolt pulls up the wedge block, the wedge will push the movable roller away from the fixed wheel, that is to say, the gap between the two rollers will be larger, and the discharge particle size will be smaller when the wedge is downward. The gasket device adjusts the size of the discharge granularity by increasing or decreasing the number or thickness of the gasket. When the gasket is added, the gap between the two rollers becomes larger, and when the gasket is reduced, the gap between the two rollers becomes smaller and the discharge particle size becomes smaller.

技术参数

technical parameter

型号

|

2PG0425

|

2PG0640

|

2PG0740

|

2PG0850

|

2PG1060

|

2PG1260

|

2PG1560

|

辊直径(mm)

|

Ф400

|

Ф600

|

Ф700

|

Ф800

|

Ф1000

|

Ф1200

|

Ф1500

|

辊宽(mm)

|

250

|

400

|

400

|

500

|

600

|

600

|

600

|

入料粒度(mm)

|

≤25

|

≤25

|

≤25

|

≤25

|

≤30

|

≤30

|

≤30

|

排料口(mm)

|

2-8

|

2-8

|

2-8

|

2-8

|

2-10

|

2-10

|

2-10

|

处理能力(t/h)

|

5-10

|

10-20

|

15-30

|

20-40

|

30-50

|

40-70

|

60-110

|

配动力型号

|

Y132M-6

|

Y180L-6

|

Y200L-4

|

Y225M-4

|

Y250M-4

|

Y315M-6

|

Y315L-6

|

电机功率(kw)

|

5.5×2

|

15×2

|

30×2

|

45×2

|

55×2

|

75×2

|

110×2

|

砂石设备

砂石设备