砂石设备

砂石设备

细碎机

发布:admin 浏览:

细碎机

Fine crusher

产品介绍

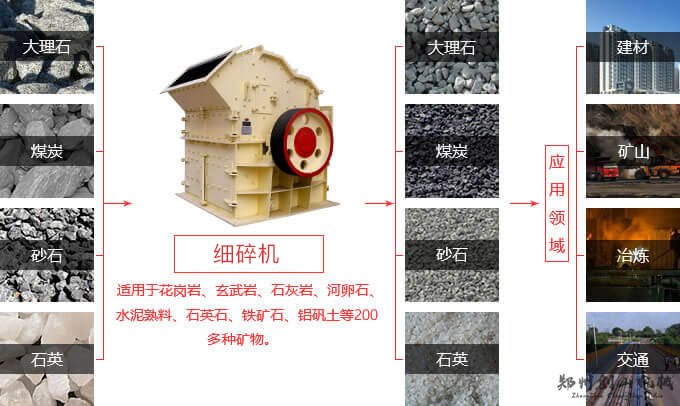

细碎机,又称细碎机、新型细碎机。该机械用途广泛,其性能已达到较高水平,是目前行之有效,实用可靠的碎石机器,具有结构简单、维修方便、部件标准化等优点。现广泛应用于矿山、冶炼、建材、公路、铁路、水利和化学工业等众多行业,主要适用于细物料,加工成品呈立方体,产品粒形好,单位运行花费少,出料粒度可达0-10mm。

Product introduction

Fine crusher, also known as fine crusher, new fine crusher. The machine is widely used, and its performance has reached a high level. It is an effective, practical and reliable stone crushing machine. It has the advantages of simple structure, convenient maintenance and standardization of components. It is widely used in mining, smelting, building materials, highway, railway, water conservancy and chemical industry and many other industries. It is mainly used for fine materials. The finished products are cubic in shape, with good grain shape and low unit operation cost. The discharge particle size can reach 0-10 mm.

产品性能

细碎效率高: 采用篦板的设计、钢性硬挤压破碎,使得细碎效率大大提高。

易损件使用时间长: 采用耐磨件材质制作,比较耐用。

运转率高,功耗低: 高线速度,运转快;节电降耗比传统的辊压机好。

方便维护: 标准化的配件与备用件,方便维护、安全可靠

Product performance

High crushing efficiency: the grate plate design and rigid hard extrusion crushing make the fine crushing efficiency greatly improved.

Long service life of wearing parts: it is made of wear-resistant parts, which is more durable.

High operation rate, low power consumption: high speed, fast operation; better power saving and consumption reducing than traditional roller press.

Convenient maintenance: standardized accessories and spare parts are convenient for maintenance, safe and reliable

工作原理

细碎机工作时,第三代制砂机在电机的带动下,转子高速旋转,物料进入一破碎腔破碎与转子上的板锤撞击破碎,然后进入二细碎腔进行粉碎,后从出料口排出。

working principle

When the fine crusher works, driven by the motor, the rotor of the third generation sand making machine rotates at a high speed, and the materials enter the first crushing chamber to crush with the plate hammer on the rotor, and then enter the second fine crushing chamber for crushing, and then discharge from the discharge port.

技术参数

technical parameter

|

PXJ 细碎机 |

转子×宽度

(mm) |

转子×宽度

(mm) |

转子×宽度

(mm) |

转子×宽度

(mm) |

转子×宽度

(mm) |

转子×宽度

(mm) |

转子×宽度

(mm) |

转子×宽度

(mm) |

|

型号规格 |

800×400 |

800×600 |

800×800 |

1010×1010 |

1200×1200 |

1400×1400 |

1600×1600 |

1800×1800 |

|

进料口尺寸(mm) |

400×185 |

500×250 |

550×300 |

1000×350 |

1200×450 |

1500×500 |

1600×550 |

1800×800 |

|

进料尺寸 (mm) |

< 120 |

< 180 |

< 180 |

< 180 |

< 180 |

< 190 |

< 190 |

< 190 |

|

出料粒度(mm) |

0-10 |

0-10 |

0-10 |

0-10 |

0-10 |

0-10 |

0-10 |

0-10 |

|

出料缝调节宽度 (mm) |

5-50 |

5-50 |

5-50 |

5-50 |

5-50 |

5-50 |

5-50 |

5-50 |

|

水泥熟料(t/h) |

10-30 |

18-40 |

20-45 |

25-55 |

50-110 |

50-150 |

85-210 |

125-270 |

|

石灰石(t/h) |

18-45 |

23-55 |

28-65 |

35-75 |

45-100 |

50-150 |

95-260 |

140-310 |

|

配备功率(kw) |

37 |

37 |

45 |

55 |

110 |

160 |

250 |

315 |

|

理论重量(t) |

3.9 |

4.5 |

6 |

10.5 |

14.4 |

22 |

35 |

49.7 |

砂石设备

砂石设备