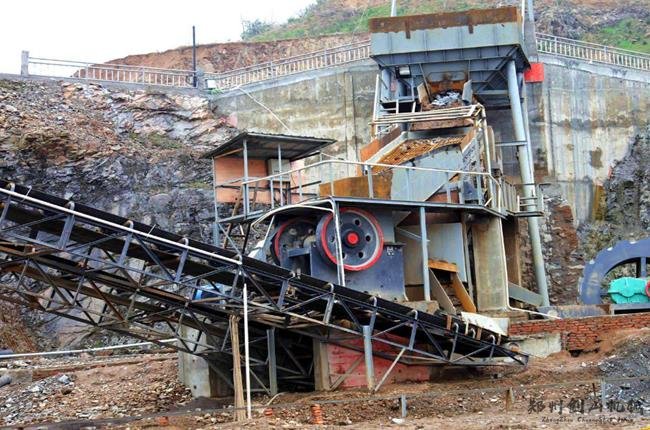

石料生产线

石料生产线

制砂生产线

发布:admin 浏览:

制砂生产线

System sand production line

我公司生产的全套制砂生产线设备,为您提供全面的技术支持,制砂生产线通常由振动给料机、颚式破碎机、VI系列立式冲击式破碎机(制砂机)、振动筛、洗砂机、胶带输送机、集中电控等设备组成;设计产量一般为50-500吨/小时。我公司历经数年的开发研究,将具有国际先进水准的VI系列立式冲击式破碎机(制砂机)与公司其他系列产品相配套,设计出的全套制砂生产线,处于行业领先地位。郑州创山机械设备有限公司设计生产的全套制砂生产线设备可用于硬质石灰石、花岗石、玄武岩、河卵石、冶多渣等多种物料的骨料及人工造砂作业,适用于水电、建材、高速公路、城市建设等行业的应用。郑州创山机械设备有限公司根据不同的工艺要求,对各种型号的设备进行组合,满足客户的不同工艺要求。

The complete set of sand production line equipment produced by our company can provide you with comprehensive technical support. The sand production line is usually composed of vibrating feeder, jaw crusher, VI series vertical impact crusher (sand making machine), vibrating screen, sand washing machine, belt conveyor, centralized electric control and other equipment; the design output is generally 50-500 T / h. After several years of development and research, our company will have the international advanced level VI series vertical impact crusher (sand machine) and other series of products of the company, designed a complete set of sand production line, in the industry leading position. The complete set of sand production line designed and produced by Zhengzhou Chuangshan mechanical equipment Co., Ltd. can be used for aggregate of hard limestone, granite, basalt, river pebble, smelting slag and other materials and artificial sand making operation, which is suitable for the application of hydropower, building materials, expressway, urban construction and other industries. Zhengzhou Chuangshan Machinery Equipment Co., Ltd. combines various types of equipment according to different process requirements to meet different process requirements of customers.

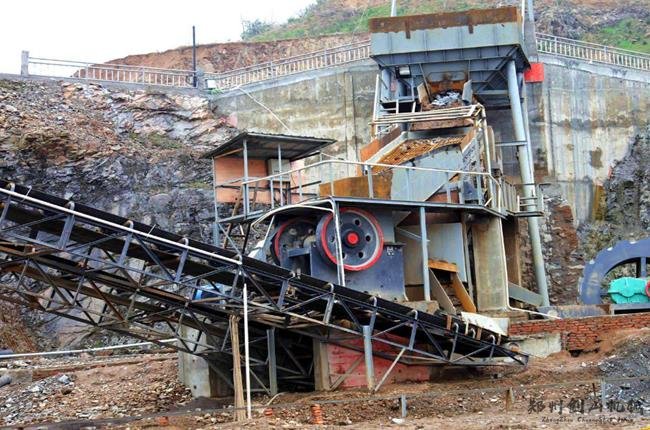

一、制砂生产线基本流程介绍

石料由振动给料机均匀地送到颚式破碎机进行粗破,粗破后的物料由胶带输送机送入到制砂机进行进一步破碎,细碎后的物料被输送到振动筛进行筛分,达到成品粒度要求的物料被送入洗砂机清洗,清洗后由成品输送带输出即为成品;未达到成品粒度要求的物料从振动筛返回制砂机重新加工,形成闭路多次循环。成品粒度可按用户的需求进行组合和分级。如果选用干法生产工艺,可配备粗细粉分离机和除尘设备。

1、 Introduction to basic process of sand production line

The stone is evenly sent to jaw crusher by vibration feeder for rough crushing. The coarse broken materials are sent to the sand making machine for further crushing by belt conveyor. The fine crushed materials are transported to the vibrating screen for screening. The materials meeting the requirements of finished product particle size are sent to the sand washing machine for cleaning. After cleaning, the finished products are output by the conveyor belt of finished products, and the materials that do not meet the requirements of finished product particle size are sent from The vibrating screen is returned to the sand making machine for reprocessing, forming a closed circuit and multiple cycles. The granularity of finished products can be combined and graded according to the requirements of users. If dry production process is selected, coarse and fine powder separator and dust removal equipment can be equipped.

二、制砂生产线性能介绍

该制砂生产线自动化程度高,运行成本低,破碎率高,节能,产量大,污染少,维修简便,生产出的机制砂符合国家建筑砂标准,产品粒度均匀,粒形好,级配合理。

该制砂生产线设备配置主要依据客户对石料规格以及产量和石料的用途来确定,我们提供售前、售中、售后的全面服务,依据客户生产现场来配置流程,力求为客户做到最合理、最经济的生产线。

郑州创山机械设备有限公司生产设计的破碎筛分联合设备在工艺流程的设计中,由于各级破碎设备匹配合理,以及严谨的空间交叉布局,因此它具有占地面积小,投资经济效益高,碎石料品质好,石粉产出率低等的特点为,同时配有先进的电控操作系统,确保了整个流程出料通畅,运行可靠,操作方便,高效节能。

2、 Introduction to linear energy of sand making production

The sand production line has the advantages of high automation, low operation cost, high crushing rate, energy saving, large output, less pollution and simple maintenance. The manufactured sand meets the national construction sand standard, and the product has uniform particle size, good grain shape and reasonable gradation.

The equipment configuration of the sand production line is mainly determined by the customer's specification, output and use of stone. We provide comprehensive services before, during and after sales, and configure the process according to the customer's production site, so as to achieve the most reasonable and economic production line for customers.

Zhengzhou Chuangshan Machinery Equipment Co., Ltd. produced and designed the crushing and screening combined equipment. In the process design, due to the reasonable matching of all levels of crushing equipment and rigorous spatial cross layout, it has the characteristics of small floor area, high investment economic benefit, good quality of crushed stone and low stone powder output rate. At the same time, it is equipped with advanced electronic control operation system to ensure the integration of the equipment Each process has smooth discharging, reliable operation, convenient operation and high efficiency and energy saving.

石料生产线

石料生产线